Author Archives: MWVeera

SBR System

Aerobic SBR’s (Sequence Batch Reactor) are unique activated sludge configurations.

Aerobic SBR’s (Sequence Batch Reactor) are unique activated sludge configurations.

SBR is distinguished by the repeating sequence of fill, react, biomass settling, and effluent withdraw which all occur within one tank.

Continue Reading →

Ultra & Nano Filtration

Membrane filtration is a technique which is used to separate particles.

Membrane filtration is a technique which is used to separate particles.

Pre-Treatment

Primary Treatment is the first and basic important stage of the water treatment process.

The purpose of the pre-treatment is to remove most of the non-soluble solids physically in order to reduce the pollutant loads and to protect all the subsequent steps in the treatment plant.

The purpose of the pre-treatment is to remove most of the non-soluble solids physically in order to reduce the pollutant loads and to protect all the subsequent steps in the treatment plant.

Providing a reliable, high-quality supply of treated water is critical to many processes. However, selecting the right Pre-Treatment technologies is very essential in the field of water treatment.

It requires a comprehensive evaluation of the raw water quality and process requirements, the system design, operating conditions, and economics. We MENA-Water have the experience and expertise to specify the right pre treatment system for standard applications and custom design systems to meet specialized needs.

Pre-Treatment incorporates the following processes:

- Screening step which aims for removal of solids

- Washing compactor cleans/compact fibrous materials from the screen for easy handling

- Grit removal step aimed for settling of all sand with larger in size than 0.15 mm

- Sand classifier and sand washer are used to wash the sand and dry it for reuse

- Grease & oil removal by floating to the surface by air and thereby skimming off

Multi Rake Screen

Multi Rake Bar Screen was developed to deal with particular problems associated with sewage pre-treatment plant.

Perforated Belt Screen

The waste water flows through perforated filter elements made of stainless steel.

Grab Screen

The waste water flows through a grating screen made of steel or stainless steel.

Step Screen

Step Screens are a ”stepping” type of screening systems for separating suspended solids.

Step Screens are a ”stepping” type of screening systems for separating suspended solids.

Inclined Drum Screen

Screw screen compactor with reinforced shaftless spiral for channels.

Vertical Screw Screen

This screw-screen-press-system is suitable for vertical installation as combined machine.

This screw-screen-press-system is suitable for vertical installation as combined machine.

Basket Screen

The basket screen is excellent for installation in pumping stations and manholes.

The basket screen is excellent for installation in pumping stations and manholes.

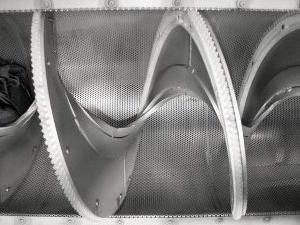

Storm Water Screen – Horizontal Screen

This is a belt screen of horizontal design.

This is a belt screen of horizontal design.

Secondary Treatment

Secondary treatment is designed to substantially degrade the biodegradable organic matter and suspended solids.

The majority of municipal plants treat the settled sewage liquor using aerobic biological processes.

This pollution mainly derived from human waste, food waste, soaps, detergent etc.

To be effective, the biota requires both oxygen and food to live. The bacteria and protozoa consume biodegradable soluble organic contaminants. (e.g. sugars, fats, organic short-chain carbon molecules, etc.) and bind much of the less soluble fractions into flocs. The final step in the secondary treatment stage is to settle out the biological floc or filter material through a secondary clarifier and to produce sewage water containing low levels of organic material and suspended matter.

Used Equipment:

- Diffuser different style for aeration.

- Mixer for mixing and avoiding of sedimentation

- Scraper different style to collect and remove settled sludge

- Scum and oil removal [Skimmer] for removal of floating material

Fine & Coarse Bubble Diffusers

Fine bubble diffusers are mainly used for oxygen transfer into biological wastewater treatment.

Mixers

Mixers are widely used in water & wastewater treatment plants.

Mixers are widely used in water & wastewater treatment plants.

Chain Scraper

The most common chain scraper system scrapes sludge from the bottom and skims surface of the tank.

The compact Cloth Screw filter units can be used in many applications of micro-filtration in order to reduce fine suspended solids from water down to 20 microns.

The compact Cloth Screw filter units can be used in many applications of micro-filtration in order to reduce fine suspended solids from water down to 20 microns.

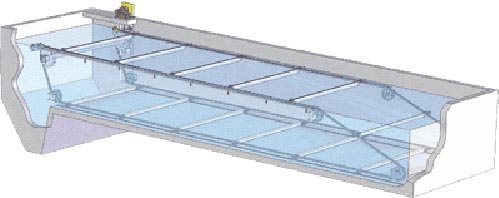

Longitudinal Bridge scrapers are designed for desludging and descuming of primary and final settling tanks and can be used as Grit chamber scrapers, sludge scrapers in the treatment plants.

Longitudinal Bridge scrapers are designed for desludging and descuming of primary and final settling tanks and can be used as Grit chamber scrapers, sludge scrapers in the treatment plants.